Consumer Product Rendering Case Study: Virtual Photography

Case Studies Photorealistic Product

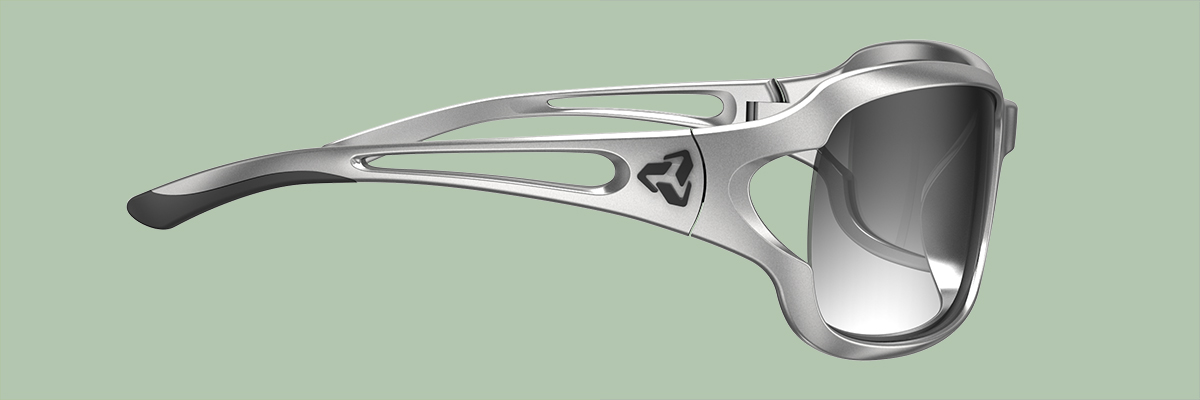

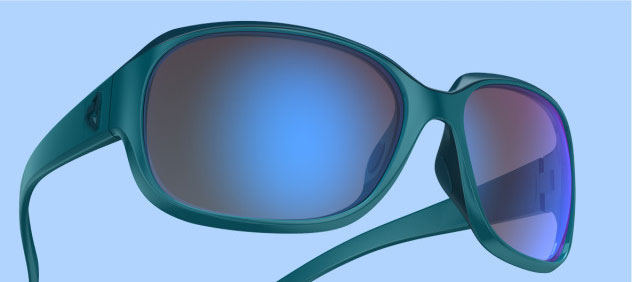

Virtual photography, also known as photo-realistic 3D rendering helped Ryders Eyewear streamline their process.

Many consumer product companies already use 3D CAD for manufacturing purposes. Using this existing 3D CAD geometry, we were able to create a virtual photo booth and render the entire product styles and colours for catalogue and website assets.

What was originally a challenge to photograph has been greatly simplified – with greater consistency and attention to detail.

How 3deeit’s Virtual Photography Rendering Streamlined Our Client’s Product Photography & Printing Process for Marketing Collateral

The Challenge: Slow Production Speeds at Every Stage

In January 2015, premium sport & cycling eyewear manufacturer Ryders Eyewear came to 3deeit with a very understandable frustration regarding product photography: specifically, the time it took to prepare the final materials for print and online marketing purposes.

Prior to contacting 3deeit, the process required painstakingly photographing all of their products, one at a time. With up to 30 different product models and eight or more colours and patterns for each one, this was a very slow and tedious practice.

The challenge was made that much more difficult by trying to achieve the same angle in every shot, but the biggest issue – and risk – was that Ryders Eyewear had to wait for physical product samples to arrive for photoshoots, making it difficult to print catalogues for the following year.

The Solution: Photoreal Product Rendering for a Faster, More Efficient Process

When Ryders Eyewear came to 3deeit, we seized on the opportunity to utilize realistic consumer product rendering via virtual photography to help streamline the process. Our goal was to provide a much faster turnaround time while maintaining superior photo quality for all products.

We started by using the same 3D CAD files for manufacturing, well before the physical samples arrived, helping us save time right off the bat.

For the product rendering shots themselves, we used the same lighting for each product, so each colour and pattern looked like it was in the same setting. Colours were also matched to Pantone samples for maximum quality and accuracy.

All of this meant that an originally complex, time-consuming process became a much faster, much simpler job with greater consistency and much more attention to detail.

The Results: High Quality, Realistic Product Photos With Faster Turnaround

When all was said and done, our photoreal consumer product rendering process yielded six individual angles for each product, providing Ryders Eyewear with a much wider variety of options for how they can be displayed across various collateral.

All files were rendered at print resolution for use in all marketing collateral. They were also all supplied in photoshop PSD format on transparent backgrounds for further ease of use.

The overall turnaround time was much faster than the previous process, and we were able to provide them with a final product well before their deadlines to print and web.

Ryders Eyewear found the final results to be so much to their satisfaction that, in the years since we initially took on this challenge, they have been trusting 3deeit with this same project when it comes time for fresh marketing photography, as well as adding product animations.

GET IN TOUCH

3deeit is a full service 3D animation studio based in Squamish, B.C., specializing in technical and product animations and engineering graphics for trade-show videos, instructional videos, product marketing videos and more!

Array